The use of base oils for lubricating purposes has a long history. It seems that the Egyptians were the first to use oil to lubricate the wheels of carts and chariots. Later, during the industrial revolution, the need for industrial lubricants was felt. In fact, new machines need to use greases continuously. At that time, greases and lubricants with simpler formulations compared to today’s greases were used. With the passage and development of machines, the need for greases that have high lubricating power, antioxidant properties, heat resistance and wear resistance will be felt.

In the following, we will talk about the types of base oils for the production of lubricants.

Types of base oils

Based on research conducted by the American Petroleum Institute, base oils can be divided into 5 categories. The first, second and third category are oils that are prepared and produced through the refining of crude oil. The fourth group, which is referred as synthetic oils, are oils that are produced in laboratories and specialized centers. A machine may use a special oil for lubrication and not use lubricants of the first to third groups; So, the owners of that company, by consulting and expressing their desired physical and chemical characteristics, can receive the right oil with their desired formulation from the laboratories. In the fifth category of base oils, there are oils that are not included in the first to fourth categories. A brief explanation has been given so far. In the following, we will discuss each of them in more detail.

Group 1 base oils

As the first generation of base oils, they are obtained from crude oil and are produced using simpler refining methods than other groups. These oils have certain characteristics due to their molecular structure and production process, some of the most important of which are mentioned below:

Physical characteristics

Viscosity

These oils usually have a higher viscosity than base oils from other groups. Viscosity means fluid’s resistance to flow, and in oils, viscosity affects lubrication performance, wear resistance, and oil film formation. The viscosity of this group of oils is between 12.1 and 68.00 mm2/s at a temperature of 40 degrees and between 3 and 9 mm2/s at a temperature of 100 degrees.

Pour Point

The pour point is the temperature at which the oil begins to lose its fluidity and turns into a solid or semi-solid state. The pour point of group 1 oils is between -12 and- 15 degrees Celsius.

Viscosity index

Viscosity index indicates changes in oil viscosity with temperature changes. Group 1 base oils usually have a lower viscosity index, meaning that their viscosity decreases sharply with increasing temperature. The viscosity index of the first group oils is between 80 and 120.

Density: oil density refers to the ratio of mass to its volume. The density of this type of oil at 15 degrees Celsius is between 860 and 865 kg/m3.

Chemical properties

Molecular structure

Group 1 oils have a more complex molecular structure than synthetic base oils. This structure includes aromatic, paraffinic and naphthenic compounds.

Sulfur content

These oils typically contain more sulfur than higher quality base oils. Sulfur can cause corrosion in metal parts and reduce the performance of additives.

Oxidation stability

Group 1 oils are more sensitive to oxidation due to the presence of more unstable compounds. Oil oxidation can cause the formation of sludge, acids and deposits that damage the engine.

Solubility

Group 1 oils usually have a higher solubility that can dissolve impurities and solid particles in the oil.

Applications of group 1

Due to the mentioned characteristics, Group 1 base oils are usually used in applications that do not require very high performance and long-term stability. Some of the common uses of these oils are:

- Engine oils for older cars

- Industrial oils with low operating temperature

- Greases

- Cutting oils

Limitations group 1 base oil

Low thermal stability: these oils may decompose at high temperatures and cause the formation of deposits.

Low oxidation stability: these oils oxidize quickly and lose their properties.

Low viscosity index: large changes in viscosity with temperature changes can negatively affect oil performance.

Group 2 base oils

These oils are produced by the hydrocracking process, which leads to a significant improvement in their properties compared to Group 1 oils.

Key features of Group 2 base oils:

High saturation level

more than 90% of oil molecules are saturated. This feature increases the oxidation and thermal stability of the oil.

Low sulfur level

There is less than 0.03% sulfur in these oils. Reducing the amount of sulfur reduces corrosion in metal parts and increases the life of the oil.

High viscosity index

between 80 and 120. High viscosity index means low viscosity change of oil with temperature change. This feature makes the oil smoother at low temperatures and sufficient viscosity at high temperatures.

Lighter Color

Group 2 oils are lighter in color due to their higher purity than Group 1 oils.

High thermal and oxidation stability

the saturated molecular structure of these oils makes them more resistant to thermal decomposition and oxidation.

Stable viscosity

The viscosity of these oils changes less under the influence of temperature and shear.

High purity

the precise production process removes many impurities and improves the purity of the oil.

Applications of group 2 base oils

Group 2 base oils are used in a wide variety of applications due to their favorable properties, including:

Engine oils: in light and heavy gasoline and diesel engines

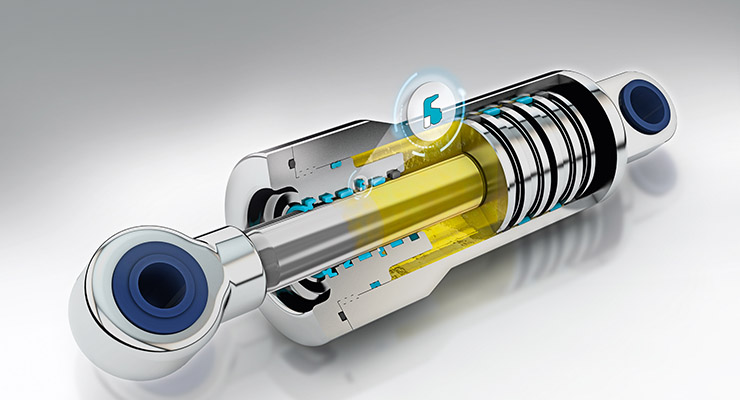

Industrial oils: in hydraulic systems, compressors, turbines, etc.

Power transmission oils: in gearboxes and differentials

Lubricating oils: in food, pharmaceutical and marine industries

Group 3 base oils

Group 3 base oils, as one of the most important types of mineral base oils, have been widely used in various industries due to their outstanding properties. These oils are produced using advanced refining processes and have greater purity and stability than base oils of lower groups.

Outstanding physical features

High viscosity index (VI)

one of the most important characteristics of group 3 oils is their very high viscosity index. This feature makes oil viscosity change less with temperature change. In other words, these oils have better fluidity at low temperatures and are more resistant to viscosity reduction at high temperatures.

Low pour point

Group 3 oils have a lower pour point due to their more regular molecular structure. This feature makes these oils maintain their fluidity even at low temperatures and prevent the formation of paraffin deposits.

High oxidation stability

Group 3 oils are highly resistant to oxidation. This feature increases the useful life of the oil and prevents the formation of acids and sludge in the engine.

Low volatility

group 3 oils have lower volatility than base oils of lower groups. This feature reduces oil consumption and reduces environmental pollution.

Transparency and bright color

Group 3 oils are transparent and have a bright color due to their high purity.

Outstanding chemical properties

Low percentage of aromatic compounds: Group 3 oils have a low percentage of aromatic compounds. These compounds can cause corrosion of metal parts, and for this reason, reducing their percentage in oil increases the useful life of the parts.

Low percentage of sulfur: Group 3 oils have a very low percentage of sulfur. Sulfur can cause corrosion and wear in metal parts, and for this reason, reducing its percentage in the oil improves the performance of the oil.

Applications of group 3 base oils

Due to the prominent features of group 3 base oils, they are used in the production of various industrial and automotive oils. Some of the most important uses of these oils are:

Motor oils: Group 3 base oils are used in the production of high quality motor oils due to their high viscosity index, high oxidation stability and low pour point.

Gearbox oils: These oils are also used in the production of gearbox oils and increase the useful life of the gearbox and reduce friction.

Hydraulic oils: Group 3 base oils are also used in the production of hydraulic oils due to their high viscosity index and thermal stability.

Turbine oils: These oils are also used in the production of turbine oils and increase efficiency and reduce the wear of turbine parts.

Group 4 base oils

Group 4 base oils, or polyalpha olefins (PAO), are a type of synthetic base oil widely used in various industries due to their unique properties. These oils are very chemically stable and resistant to oxidation, heat and pressure.

Physical characteristics

Very high viscosity index

This feature means that the viscosity of the oil changes little with temperature changes. In other words, PAO oils do not become too thin at high temperatures and do not become too thick at low temperatures. This feature makes these oils perform well in a wide range of temperatures.

Very low pour point

This property means that the oil is resistant to solidification at low temperatures. This feature is very important for low temperature applications.

High flash point

This feature means the oil’s resistance to ignition. This feature is very important for applications that are exposed to high temperatures.

Low volatility

This feature means low oil evaporation. This feature makes the oil last longer and requires less replacement.

Clarity and light color: PAO oils are usually clear and colorless.

Chemical properties

High oxidation stability

PAO oils are highly resistant to oxidation. Oxidation causes the formation of deposits and acids that can damage the engine.

High thermal stability

PAO oils are very resistant to heat. Heat causes the oil to break down, which can damage the engine.

High chemical stability

PAO oils are highly resistant to chemicals such as acids and bases.

Low polarity

PAO oils have very low polarity. This feature prevents these oils from mixing with water and preventing the formation of emulsions.

Advantages of using group 4 base oils:

Better engine performance

PAO oils reduce friction, reduce wear and increase engine life.

Reduced fuel consumption

PAO oils reduce fuel consumption due to reduced friction.

Reducing the emission of pollutants

PAO oils reduce the emission of pollutants due to the reduction of fuel consumption and the reduction of sediment formation.

Suitable for harsh applications

PAO oils are very suitable for applications that are performed in harsh conditions such as high temperatures, high pressure and high speed.

Applications of group 4 base oils

Motor oil

PAO oils are used in the production of high performance synthetic motor oils.

Gear oil

PAO oils are used in the production of automatic and manual gearbox oils.

Hydraulic oil

PAO oils are used in the production of hydraulic oil.

Compressor oil

PAO oils are used in the production of compressor oil.

Turbine oil

PAO oils are used in the production of turbine oil.

Summary

In general, group 1 base oil has become obsolete over time and is replaced by group 2 and 3 base oils. Blackwater company provides the best quality base oils using distillation towers and advanced reactors.

No comment